Differential (top & bottom) full profile laser scan for accurate board measurement

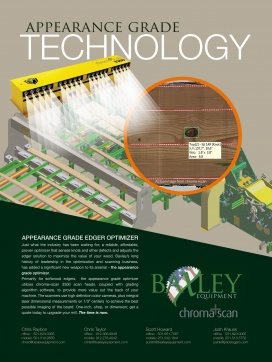

– Dynavision Chroma+Scan 3350 scanner heads

- All related FireSync hardware

- Chroma+Scan sensors

- Thickness laser scan lines on 8mm nominal centers

- Two profile cameras per head

- Thickness accuracy ±. 0.010″

- Two profile cameras-per-head for improved scan data

- 2000 profile scans-per-second

- Gigabit Ethernet link to optimizer computer

– Color image sensors for visual defect detection

- 80 image scans-per-second

- Edger program to see and identify knots to improve edging for grade performance

– Rigid accessible scan frame

- Pre-wired, shop calibrated and shop tested

- Laser air knife (complete with 5HP blower)

– Computer chassis with:

- 2.3Ghz Intel Quad core processor with 4Gb RAM

- DVD-RW internal drive

- One (1) 32Gb Intel solid state drive as primary drive

- One (1) high-capacity SATA Hard Drive for data and backup storage

- Dual redundant power supplies

- Ethernet link to PLC

- 19” flat panel SVGA video monitor and keyboard

- 15’ video, keyboard, and mouse cable

- New USB Keyboard and Optical Mouse w/ scroll wheel

– User friendly Windows 7 based optimization software, with features including:

- 3D graphical user interface. Intuitive “point and click” operation. All mechanical and product parameters easily accessed and edited from pull down menus

- Password protection capability

- Product parameter “modeling” visually displays product parameters to eliminate mis-defined products

- Expanded product evaluation capability

- Up to 24 product lengths

- Up to 16 product widths

- Up to 16 grade/thickness combinations

- Up to 550 products

- Comprehensive diagnostic functions with easy to understand details of why a particular solution was chosen.

- Online Help manual with Hypertext links to other help topics.

- Comprehensive production reporting capability (up to three shifts per day)

- Optimizer computer hard drive storage of shift data (up to two year capacity)

- Report printing capability for any number of shifts, to any LAN printer on the network (i.e. in the main office or other remote computer).

- Shift data logged on ten-minute intervals for 48 hours

- Customized trend plot capability, Microsoft Access or Excel compatible

- QC package for length and thickness

- Re-optimization capability for testing edited parameters on saved flitches

- Re-optimization while the line is running requires a parallel computing system (not included) running under a Windows 7 operating system

- “TechScan Supervisor” optimization monitoring runs in background to monitor critical optimizer functions

- Full alarm reporting capability

- “PC Anywhere” software package for remote access and service support

- Complete documentation package